Bently Nevada Case Expansion and Valve Position Transducer Systems

2016-06-30 15:04:57

Description:

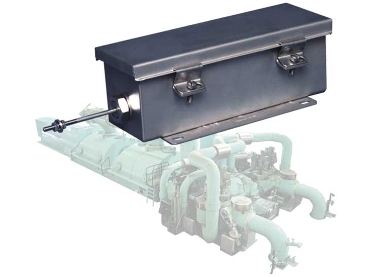

GE Bently Nevada offers a very wide variety of vibration, position, speed, pressure and power sensors and transmitters, each designed to handle the rigors of industrial environments and many capable of being installed in hazardous areas when appropriate I.S. barriers, galvanic isolation, or other means are used. An important position measurement in Turbine Supervisory Instrumentation (TSI) is case expansion. Case expansion (sometimes referred to as shell expansion) is the thermal growth of the machine case as it expands during machine startup and on-line operations. The case expansion transducer system is typically mounted on the foundation at the opposite end from where the turbine casing is attached to the foundation and provides information about the growth of the machine case relative to the foundation.……

New Products

Siemens 6DL1193-6TP00-0DH1 SIMATIC ET 200SP HA

Siemens 6DL1193-6TP00-0DH1 SIMATIC ET 200SP HA, Terminal block, Type H1, 32 push-in terminals, internal reference temperature New load group, width: 22.5 mm.

Siemens 6DL1193-6TP00-0BH1 SIMATIC ET 200SP HA

Siemens 6DL1193-6TP00-0BH1 SIMATIC ET 200SP HA, Terminal block, Type H1, 32 push-in terminals, internal reference temperature Width: 22.5 mm.

Siemens 6DL1193-6GC00-0NN0 SIMATIC ET 200SP HA

Siemens 6DL1193-6GC00-0NN0 SIMATIC ET 200SP HA, carrier module 8-fold carrier for holding 8 I/O modules of the ET 200SP HA.

Siemens 6DL1193-6GA00-0NN0 SIMATIC ET 200SP HA

Siemens 6DL1193-6GA00-0NN0 SIMATIC ET 200SP HA, carrier module 2-fold carrier for holding 2 I/O modules of the ET 200SP HA.

Assortments

Description

Bently Nevada Case Expansion and Valve Position Transducer Systems

GE Bently Nevada offers a very wide variety of vibration, position, speed, pressure and power sensors and transmitters, each designed to handle the rigors of industrial environments and many capable of being installed in hazardous areas when appropriate I.S. barriers, galvanic isolation, or other means are used.

An important position measurement in Turbine Supervisory Instrumentation (TSI) is case expansion. Case expansion (sometimes referred to as shell expansion) is the thermal growth of the machine case as it expands during machine startup and on-line operations. The case expansion transducer system is typically mounted on the foundation at the opposite end from where the turbine casing is attached to the foundation and provides information about the growth of the machine case relative to the foundation.

Features and Benefits

Case expansion measurements also enable you:

To determine whether machine conditions are exceeding expected temperature growth differentials.

To determines whether the machine casing and rotor grow thermally at nearly the same rate.

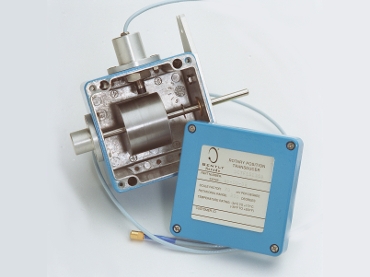

The 3300 XL Rotary Position Transducer (RPT) measures angular rotation. Its most common use is for measuring valve position on steam turbines allowing for:

Utilizing valve position information to adjust inlet valves,

Determining operating efficiency and measuring the load of the turbine.

The 18639 Valve Position Transducer measures the opening of governor valves on the steam turbine so you can

Monitor and adjust the amount of steam that flows to the individual valves in the group to provide the highest machine operating efficiency.