Smart Digital Sensors SPS24 SENCOM® PC Software

2016-05-27 11:55:06

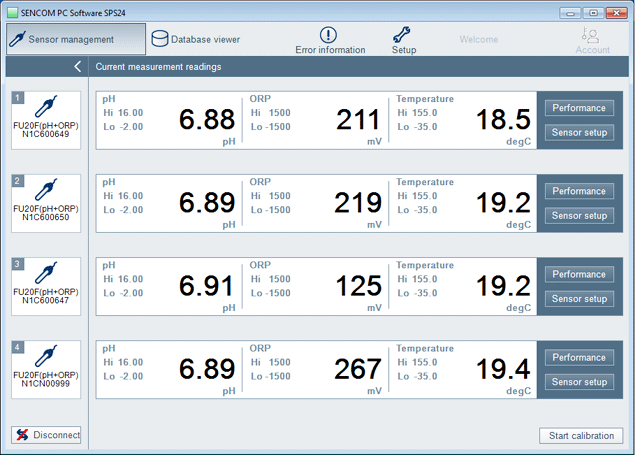

Description:

The new SENCOM® PC Software SPS24, offers a unique means to optimize the performance of pH/ORP sensors for enhanced reliability and process safety. The software allows the operator to monitor pH/ORP sensor performance, calibrate and configure various parameters.……

New Products

Honeywell 51307038-100 Power Control Module Assy

Honeywell 51307038-100 Power Control Module Assy. Honeywell Experion LX Series 8 C300 controller provides powerful and robust control for the Experion LX platform.

Honeywell 8937-HN2 Fibre Optic converter IO Module

Honeywell 8937-HN2 Multi-Mode, Fibre Optic converter IO Module. The Fiber Option Extender modules support the extension of the I/O link beyond the Series 8 cabinet with the S8 C300, enabling remote applications of the Series 8 I/O.

Honeywell 8939-HN Multi-Mode Fiber Optic Extender (IOTA)

Honeywell 8939-HN Multi-Mode Fiber Optic Extender IOTA. The Fiber Option Extender modules support the extension of the I/O link beyond the Series 8 cabinet with the S8 C300, enabling remote applications of the Series 8 I/O.

G.M. International X1-IS-AO-02-S I.S. SIL2 HART® Isolating Driver module

G.M. International X1-IS-AO-02-S I.S. SIL2 HART® Isolating Driver module. GMI Intrinsically Safe Isolators, Analog Output

Assortments

▶ Pressure Transmitter EJA

▶ Pressure Transmitters EJA-E

▶ Pressue Transmitter EJX

▶ Safety Instrumented System (SIS)

▶ Valve Positioners & Converters

▶ Field Mount Indicators

▶ Temperature Transmitters

▶ Magnetic Flowmeters

▶ Vortex Flowmeter

▶ Ultrasonic Flowmeters

▶ Coriolis Mass Flowmeters - ROTAMASS 3-Series

▶ Variable Area Flowmeters – Rotameters

▶ Device Smart Communicators

▶ PORTABLE AND HANDHELD INSTRUMENTS

▶ Distributed Control System (DCS)

▶ Process Analyzers

▶ Paperless Recorders

▶ Strip Chart Recorders

▶ Data Acquisition Equipment

▶ UT Series Temperature Controllers

▶ UP Series Program Controllers

▶ UM Series Digital Indicators with Alarms

▶ UT100 Series Temperature Controllers

▶ UD Series Manual Setters

▶ Limit Controllers

▶ YS Series Single-loop Controllers

Description

SPS24 SENCOM® PC Software

SPS24 can communicate and keep track of data for up to 100 different SENCOM® sensors and allows for manual input of data of traditional pH/ORP sensors. Simply connect your SENCOM® sensor via Interface Box and USB port to your PC and get access to intuitive analysis, sensor configuration, calibration information and documentation applications.

SPS24 allows complete control of the procedure during a pH/ORP sensor calibration, ensuring the highest accuracy every time by allowing the user to either re-use or discard a sensor based on the real-time sensor information before reinstallation into the process. The calibration information is collected and can be managed, analyzed and documented consistently to satisfy regulatory documentation requirements. The SPS24 PC Software offers various data export possibilities to guarantee protection of sensor history information in order to manage the sensor over its entire life cycle.

Ability to calibrate up to 4 sensors at one time

Monitor sensor aging in real-time with the Sensor Wellness feature

Reference impedance measurement for early detection of diaphragm clogging

Predictive calibration/maintenance using advanced sensor diagnostics

No need for sensor configuration at the transmitter, pre-configure in the lab for auto upload

Individualized password protected user accounts

Reliable transfer of digital signals without disturbance of external sources